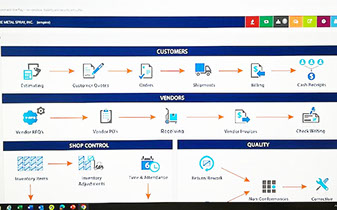

Manufacturing Process Controls

• Job Cost Survey

• Job Cost Recap

• Labor Detail

• Outside Cost Detail

• Part History

• Corrective/Preventive Action

• Feed back

• Employee Training

• Non-Conformance

• Work Center & Tooling Maint

Quality Control

Job Est & Costing

• Production Scheduling

• Time Tracking & Routing

• Work Center Breakdowns

• Operation Breakdowns

• Department Breakdowns

• Items & Transfers

• Fill Job Requirements

• Reorder Scheduling

• Usage Reporting

• Inventory Count & Analysis

Inventory Management

Job & Data Control

3755 S. Jason St. Englewood, Colorado 80110 USA

303 762 8744 800 397 8746 Fax: 303 762 8505

sales@empiremetalspray.com empiremetalspray.com

Copyright © 2024 by Empire Metal Spray, Inc.® All Rights Reserved